Wood and Paper

Product description

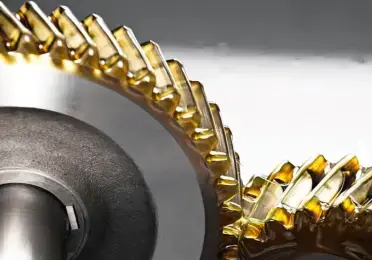

In wood and paper processing, stoppages cost money. If your company has invested heavily in equipment, it needs to be up and running in order to stay profitable. At TotalEnergies we understand the pressure wood and paper plants are under, and have developed lubricants that optimise performance and enhance the service life of your equipment.

With our technology leadership in the lubricants market, TotalEnergies products for paper processing, wood panelling and pelleting are designed to face challenges specific to the industry – high temperatures, high pressures and extreme moisture levels. We know that some processes are very energy intensive. Thanks to our R&D, we now deliver products that lower fuel and lubricant consumption, and reduce environmental impact. Our extensive product range is backed up by services that are second to none – helping you choose the right lubricant for your equipment, analysing your oils for wear and tear, and delivering on time all over the UK.

Product applications

High performance multifunctional products for wood panel

<strong>Paper industrial brochure</strong><br>

<strong>Ceran greases range for wood</strong><br>

<strong>Carter XEP for wood industry</strong><br>

IOEM approvals

- Allimand

- Voith

- Valmet

- Andritz

- CPM

- Kahl

- Salmatec

Our references in paper sector

- International Paper

- Smurfit Kappa

- Kimberley-Clark

- Georgia-Pacific

- Storaenso

- Nordic Paper

- Bohui Paper

- Chenming Group

- Arjo Wiggins

- Oji Paper

- Group Portucel Soporcel

- DS Smith

Our references in wood sector

- IKEA

- Kronospam

- Spanolux

- Egger

- Joubert

- Darbo

- Recybus

- Erda

- Europ Service Industrie

- AVV Wood

- Eco Ebepellet

- Industrie du Bois Vielsalm & Cie

What our customers say?

We were experiencing problems with our heat transfer system. Total assisted us through this difficult phase by sharing their knowledge and best practices relating to heat transfer systems. They assisted us in proper flushing of the entire system as well as heat transfer fluid charging and cooking. Their technical team visited our site and shared their experiences. After flushing our system, we changed to Total Seriola 1510, which we are still using. The oil is performing well and we have not experienced any of the previous problems. The oil’s condition is being routinely monitored by Total’s oil analysis service.

Chip Boards & Hard Boards manufacturer

It’s three years since we changed to Ceran PM and we’ve had excellent performance in aquifer stability, erosion resistance, oxidation resistance, anti-corrosion and anti-extrusion, which effectively protects the bearings of the press section. Misola MAP SH 220 has had very good performance on water separation, anti-corrosion and oxidation resistance under high load conditions, prolonging the service life of bearings and ensuring the continuous production of paper.

A leading paper and paper products manufacturer