Metalworking

Metal processing of any material type is always coming with parts of complexity to ensure quality, safety, and productivity. The technical demands and constraints on lubricants are increasingly critical to meet customer requirements, reduce environmental impact, and enhance user safety. We are actively developing a range of products for metal processing, including cutting fluids, both neat and soluble, forming and stamping fluids, and various specialty fluids for a diverse industries to pioneer sustainable solutions.

Product Description

For decades, TotalEnergies has worked with metalworking customers around the world, developing a comprehensive range of lubricants to meet your needs. Rolling, forming, quenching, cutting and more - our products are designed specifically for applications throughout the process. We know that your goals include shortening production cycles, extending tool lifetime, reducing fuel consumption and decreasing waste, and with TotalEnergies as your partner that’s what we’ll achieve.

Formulating our lubricants, we take into account you and your workers, and the environment. We’ve reduced VOC s, odours and dangerous substances across the range. Our comprehensive selection of products is backed up with technical support adapted to your requirements, and our worldwide experience working in this industry. Get in touch with TotalEnergies today and we’ll find the right solutions for your plant.

Product Applications

At a glance – a product for every application

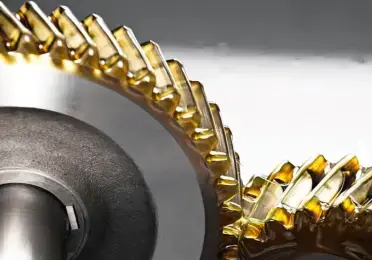

General Machining Lubricants

TotalEnergies range of machining fluids effectively lubricate metalworking equipment, protecting sawing, drilling, milling, turning, quenching and finishing operations. Providing a wide range of benefits, they can boost your business’ productivity.

What are TotalEnergies machining lubricants?

General machining and metalworking operations are reliant on machinery coping with extremes in heat and pressure, so must be properly lubricated.

Cutting Fluids

TotalEnergies cutting fluids ensure your metalworking or machining plant can operate efficiently and effectively. High-quality lubricants, they protect cutting tools working a wide range of metals, providing increased productivity for your industrial or manufacturing business.

What are TotalEnergies’ cutting fluids?

Cutting tools used for metalworking and machining commonly operate under extremes of pressure and heat, so need properly formulated lubricants to be safeguarded against unnecessary wear and damage.

Forming Fluids

TotalEnergies forming fluids help optimise industrial and manufacturing business’ operations. Lubricating bending, stamping, stretching and shaping machinery, they’re formulated to protect your equipment, lowering costs and reducing downtime.

What are TotalEnergies forming fluids?

Metal working machinery and tools performing bending, shaping, stamping and stretching operations need to be correctly lubricated in order to function effectively.

Read more metal forming oils and lubricants

Aluminium Rolling Fluids

TotalEnergies range of aluminium rolling fluids provide manufacturing plants with reliable and consistently lubricated operating lines. It’s part of our industrial lubricant metalworking range, formulated to keep your business operating at an optimum level.

What are TotalEnergies aluminium rolling fluids?

To produce aluminium plates and sheets that have high-quality edges, no defects including no staining and are uniform in thickness and width requires the use of durable yet precise metal working machinery.

Read more aluminium rolling fluids

FOLIA Water-based metalworking fluids

The TOTALENERGIES FOLIA range of metalworking lubricants is free from oils and solvents of any kind – truly game-changing for industrial markets.

The water-based range provides many performance and environmental benefits; delivering enhanced efficiency, reduced long-term maintenance costs and cleaner machinery.

Technical resources

Metalworking brochure

Aluminum processing fluids

Thermal systems manufacturing

They Trust US

End customer approvals

- Airbus Group

- Nestle

- PSA Peugeot Citroen

- Valeo

- Volkswagen

IOEM approvals

- Achenbach Buschhutten

- FATA Hunter

- ONA

- KAPP

- Karl Klin

Our aluminium references

- Obrysmian

- Aditya Burla Hindalco

- Hydro

- Rio Tinto

- Grange Insurance

- Eurofoil

- Rusal

- Aditya Burla Novelis

- Aludium

Our fastener references

- ALCOA

- Lisi

- UGIVIS

Our heat exchanger references

- Calsonic Kansei

- Delphi

- Denso

- Evapco

- Modine

- Valeo

- Visteon

- Wesper

Our cutting tool references

- TIVOLY

Our precision turning references

- Alpen Tech

- Baud Industries

- Bontaz Centre

- Parker

- Popp + Potthoff

- Rexroth Bosch Group

- Rossignol

- Rotarex

Our gear manufacturing references

- DAF

- Fiat

TotalEnergies has demonstrated its technical capability and expertise and its strong commitment to providing the right lubricants for the right applications at our first class production site. TotalEnergies delivers innovative products and lubricating solutions.

a French manufacturer of alpine, snowboard, and Nordic equipment

From now on we’ll recommend that all our static spray machines used for food purposes will be lubricated with Martol FMO 15 CF when in operation.

of manufacturing and servicing auto-control equipments

For the last 10 years, TotalEnergies has supplied us with Martol LVG and EV forming oils, which always conform to our quality standards. Martol LVG 15(25) CF and Martol EV 10 CF are used for forming and cutting the aluminium elements of motor radiators and air conditioner condensers. We earnestly recommend TotalEnergies products and TotalEnergies as a company to other enterprises for their professionalism.

of designing and developing climate control system solutions for vehicle manufacturers

DocOnline

Contact us - Send us query