On-site lubrication expertise: Plant audit

Why do a lubrication audit?

Most of our customers are trying to increase the reliability of their machines but often struggle to achieve this objective due to a lack of staff, time and investment. Because of these pressures, machines tend to be reactively maintained, only treating the consequences, not the causes of machine failure. Also, many lubricant methods and practices have never been questioned because of the infamous, "We always have done it this way, and it's worked, so I don't see why we need to change."

Our solution

Besides supplying oil and grease, we offer our customers the opportunity to have a full on-site review to help them optimise:

- Lubricant usage in critical equipment

- Current lubrication procedures

- Lubricant handling

Common audit outcomes

What is the optimal lubricant for your equipment? Do you understand additive technology? How or when would you choose a synthetic lubricant over a mineral one?

We have many years of experience in different markets and are able to benchmark against best practice. Throughout your audit our objective is to ensure that suitable products and procedures are in place in your plant to achieve your objectives.

- Increased drain interval

- Increased equipment efficiency

- Decreased failure rates

- Extended equipment lifetime

- Rationalised use of products on-site

A brief example

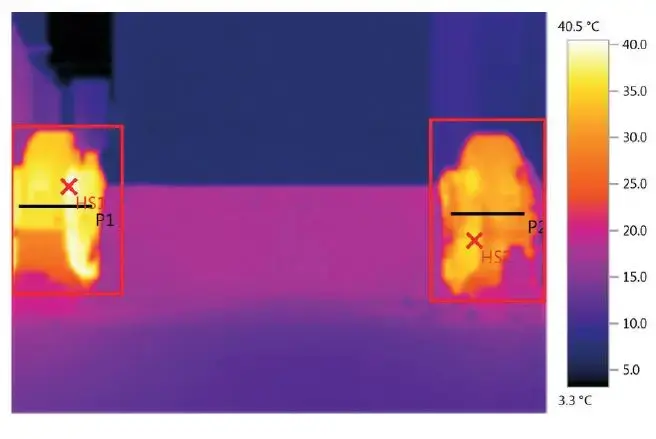

Using a thermal camera can disprove many commonly held beliefs!

Our on-site experience is that bearings are often over-greased, thus creating overheating of the inner races. Too much grease results in increased friction causing temperature to increase which will damage bearings and increase failure frequency. We can help you to calculate the correct amount of grease to be applied to each bearing.

Below is an example of temperature increase in a bearing

On the left, the bearing temperature is too high due to over-greasing. For comparison, the bearing on the right is properly greased.

Audit > |

Report > |

Review > |

KPI's > |

|---|---|---|---|

|

On site with maintenance team (on average 1 to 3 days) |

Written by TotalEnergies technical team

|

Meeting with maintenance team (Define actions to take 1/2 day) |

Improvements tracked (1 to 6 months) |

Key Facts

- 22% of maintenance managers are satisfied with their current programs

- A well planned job takes on average half as much time to execute as an unplanned job and costs 3 to 9 times less

- One out of every two pounds spent on preventive maintenance is wasted.

- Implementing an audit will help maximize equipment life and minimize scheduled and unscheduled downtime by looking at lubricant usage and predictive maintenance tools.